OatBurger Oat Malt Stout

B My wife and father in law have been bugging me for an Oatmeal Stout for quite a long time now, and I finally gave in on Saturday. . .sort of. In a twist on their request, instead of adding oatmeal to my beer, I went with Oat Malt. Why, you should ask? Well basically it is easier to brew with Oat Malt. In the mash tun, Oatmeal (Flaked Oats, whatever) if used in large enough amounts can form a big gooey mess (think breakfast time!), that can be quite detrimental to the runoff. Oat Malt, which looks and acts a lot like the traditional malted barley, does not seem to cause any of these problems, while contributing most of the benefits of the oats.

To that end, the recipe:

Recipe: #036 - OatBurger Oat Malt Stout

Brewer: Tres Perros Brewing

Style: Oat Malt Stout

TYPE: All Grain

Recipe Specifications

--------------------------

Batch Size: 6.00 gal

Boil Size: 7.50 gal

Estimated OG: 1.059 SG

Estimated Color: 32.2 SRM

Estimated IBU: 33.8 IBU

Brewhouse Efficiency: 65.00 %

Boil Time: 60 Minutes

Ingredients:

------------

Amount Item

9 lbs Warminster Floor Malted Maris Otter

3 lbs Pale Malt - 2 Row (Briess)

1 lbs Caramel Malt - 60L (Briess)

1 lbs Oats, Malted (Thomas Fawcett)

1 lbs Simpson's Chocolate Malt

1.00 oz UK Goldings [7.20 %] (60 min)

1.00 oz UK Golding [7.20 %] (15 min)

1.00 tbsp Irish Moss (Boil 10.0 min)

2.00 tbsp Yeast Nutrient (Boil 10.0 min)

10.00 gal Bottled Spring Water

1 Pkgs Yorkshire Square Ale Yeast (White Labs WLP037)

Single Infusion Mash 154*F (60min), (I batch sparge.)

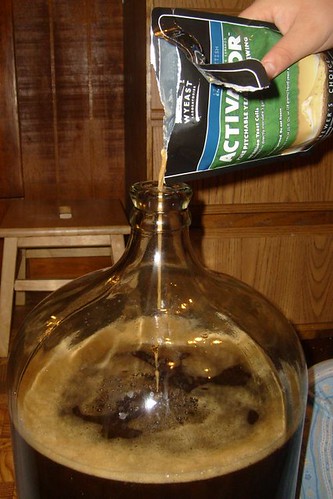

Brewday itself went pretty straight forward (will remember to take more pictures next time). My OG was 1.057 (only two points off my projected OG). Now the beer is in its third day of happily bubbling away as a yeast city. The yeast, in this case is White Labs 037 - Yorkshire Square Ale. This yeast is supposedly the strain used by Samuel Smith's. My beer, unlike the traditional English style is fermenting in a carboy, not in Yorkshire Squares. A Yorkshire Square vessel is a two-story system consisting of a shallow chamber approximately two six feet, above which is a walled deck. Cooled wort is fermented in the lower chamber, while the yeasty head settles on the deck above. During the first stage of fermentation, the fermenting wort is periodically pumped from the bottom of the chamber over the yeasty head, to keep the yeast mixed in with the wort. Later, the mixing is stopped and the wort in the chamber allowed to settle and cool gently. Most of the yeast rises onto the deck, and is left behind when the beer is drained from the chamber. The whole process takes at least six days.

The yeast used in the Yorkshire system is unusual in that it acts particularly slowly and requires frequent rousing and aerating if it is to work properly. This action is due in part to the yeast’s strongly top-fermenting qualities, which cause it to rise rapidly to the surface of the fermenting wort.

Hopefully my inability to rouse it in this way will not keep it from attenuating fully.

One last thing before I go, a short discussion on nomenclature. There seems to be a lot of fuss online on what constitutes a stout, and what is a porter. The folks on HomeBrewTalk seem to think it cannot be a stout without roasted barley. most notably that the amazing Great Lakes Brewing Porter, Edmund Fitzgerald, has roasted barley (and thus by the HBT definition, would be a stout), while Sierra Nevada's Stout has none. Finally, Zynthophile notes that while there may have been stylistic differences historically, these days there really isnt much distinguishing them besides the brewers choice of name. As a homebrewer, I like this concept best. I say it is a stout, and thusly a stout it is!

Incidentally you can follow Tres Perros on Twitter (@3PerrosHomebrew). Also, amusingly, the dog on the label of the brew I made this past weekend is not one of mine, but one of our member's (also my in-laws) dogs, Otis